crushing and grinding industry in 2011

Хөнан Лимин хүнд даацын машин механизм, шинжлэх ухаан техникийн ХК-д тавтай морилно уу. Та санал хүсэлтээ үлдээх эсвэл бизнесийн журмаар бидэнтэй холбогдож болно. Манай борлуулалтын менежер таньтай холбогдох болно.

The Evolution of Crushing and Grinding: Changes in the Industry

2010year7month1day Crushing and grinding processes have undergone significant changes over the last 20 years. These adjustments have focused on lowering costs and increasing production and energy efficiency,...

узнать больше

Applications of crushing and grinding-based treatments for

2022year12month1day It is experimentally found that close to 99.9 wt% PCDD/Fs are destroyed after grinding for 12 h with 400 rmp rotational speed using CaO–Ca as the co-grinding

узнать больше

The Effect of Fine Grinding Medium Feature on Grinding Results

2014year1month1day This article introduced an accurate to ascertain the size of fine grinding medium. Comparative grinding tests are done by using cast iron segment steel ball.

узнать больше

Grinding for food powder production - ScienceDirect

2013year1month1day Abstract: Grinding is a unit operation widely used in the food industry and designed to reduce the size of materials. These operations can be implemented

узнать больше

A review of modeling and control strategies for cone crushers

2021year8month15day Additionally, from the theoretical point of view, crushing performance in the quarrying and mining industries have different optima (Lee and Evertsson, 2011). This

узнать больше

Crushing and Grinding Industrial Engineering Chemistry

Crushing and Grinding. Lincoln T. Work. Cite this: Ind. Eng. Chem. 1948, 40, 1, 9–10. Publication Date: January 1, 1948. https://doi/10.1021/ie50457a004. RIGHTS

узнать больше

Crushing and grinding Industrial Engineering Chemistry

2021year3month12day Crushing and grinding. Lincoln T. Work. Cite this: Ind. Eng. Chem. 1947, 39, 1, 11. Publication Date: January 1, 1947. https://doi/10.1021/ie50445a008.

узнать больше

Influence of Natural Aggregate Crushing Process on Crushing

2021year7month27day Resistance to grinding is related to the strength of the products made from aggregates subjected to grinding, which affects the overall quality of these products.

узнать больше

Crushing SpringerLink

Home. Materials Beneficiation. Chapter. Crushing. Charles Burroughs Gill. Chapter. 247 Accesses. 1 Citations. Part of the Materials Research and Engineering book series

узнать больше

Crushing SpringerLink

Abstract. The size to which particles are reduced is governed by three criteria: the particle size of the mineral grains in an ore which are to be liberated for later separation and collection into a concentrate; and. the exposure of mineral grains for dissolution by a leaching process which is to follow.

узнать больше

Grinding (Comminution) - an overview ScienceDirect Topics

The comminution is done in two stages: (1) Crushing and (2) Pulverizing/grinding. 9.7.2.1. CrushingCrushing of samples is required when grain sizes are too large for pulverizing equipment. This volume reducing process is normally applied to large sample types such as rocks and core. ... 2011. 6.1 Gel Grade. Generally, it is very similar to the ...

узнать больше

Crushers, breakers and grinding mills for the mining industry

Crushers, breakers and grinding mills come in several different types. Mining Technology has listed some of the leading suppliers of processing equipment in the mining drills and breakers market, based on its intel, insights and decades of experience in the sector. The list includes suppliers of crushers, rock breaker mining equipment, grinding ...

узнать больше

The Worldfolio: Crushing, Grinding and Separation

2023year2month6day Crushing, Grinding and Separation Technologies for a Sustainable Society. Interview - February 6, 2023. EARTHTECHNICA is a comprehensive equipment manufacturer that was born in April 2003 by integrating the technologies from Kawasaki Heavy Industries together with Kobe Steel, and today, as a member of the Kawasaki

узнать больше

Applications of crushing and grinding-based treatments for

2022year12month1day 1. Introduction. The demands for metals are universal in modern society, including the production of daily product, vehicle, infrastructure, etc (Gordon et al., 2006).Continuous growth in the demands of these products and relevant services has greatly stimulated the mining industry (Kaya, 2016; Prior et al., 2012).When the lifetime

узнать больше

Mechanochemistry: The Science of Crush — Google Arts

Crushing and grinding food are common techniques that have been used for thousands of years and in almost every human culture. They make grains and nuts more palatable and easier to digest, unlocking extra nutrition and different flavors. ... making chemistry one of the most important sciences for industry during the 1800s. Mathew Carey Lea ...

узнать больше

Henan Liming Heavy Industry Science Technology Co., Ltd.

Henan LIMING Heavy Industry Science and Technology Co. LTD which mainly manufacture large and medium-sized crushing and grinding equipments was founded in 1987.It is a modern joint-stock corporation with research, manufacturing and sales together. The Headquarter is located in HI-TECH Industry Development Zone of Zhengzhou and

узнать больше

Developments in iron ore comminution and classification

2015year1month1day However, the application of IsaMill™ in iron ore industry is more recent. In July 2011, the first IsaMill™ to grind magnetite was successfully commissioned at Xstrata Coppers' Ernest Henry Mine (EHM). The magnetite circuit at EHM is designed to treat 6 Mtpa and produce 1.2 Mtpa of magnetite concentrate.

узнать больше

Grinding materials processing Britannica

cutlery. In cutlery: Cutlery manufacture. and tempering it correctly; (3) grinding the blade to a cutting edge and removing all traces of forging and heat treatment; (4) polishing the blade; and (5) making, fitting, and polishing the handle, a process known as cutling. Read More.

узнать больше

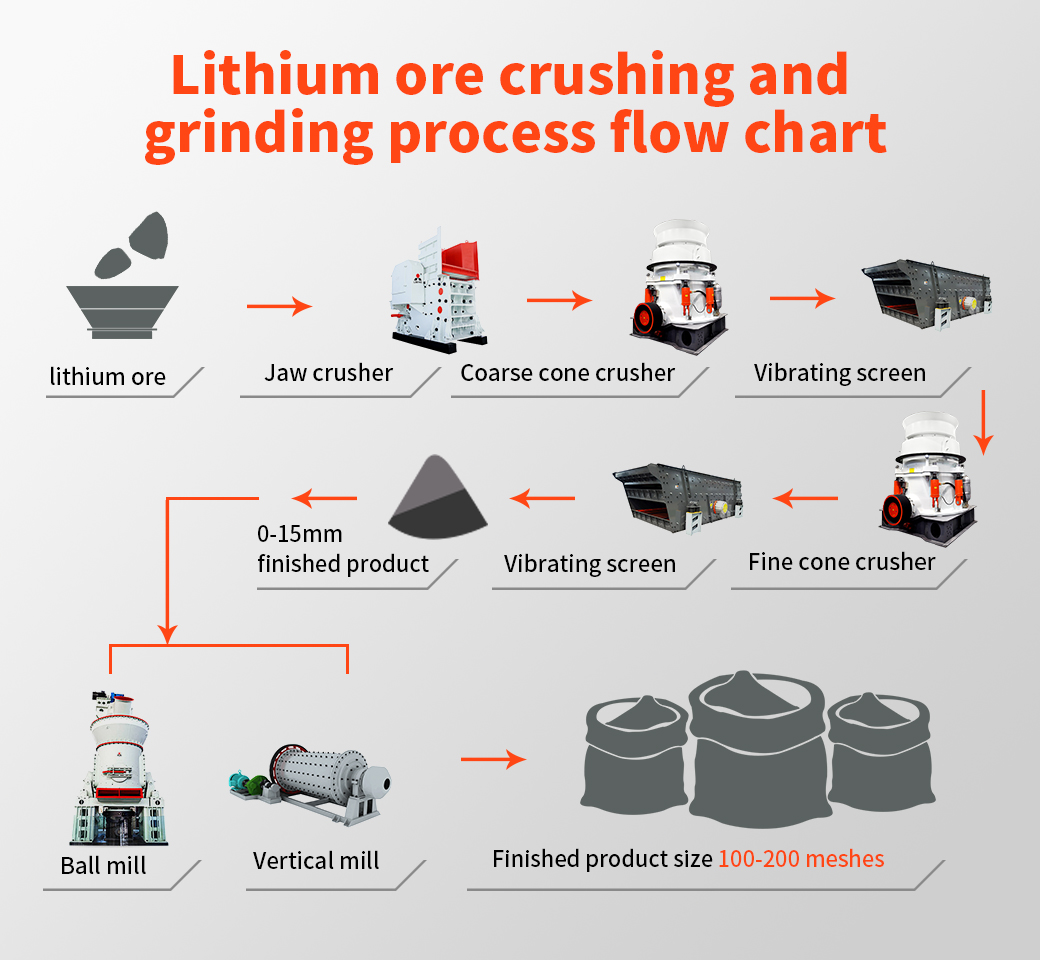

Crushing and Grinding Process - JXSC Machine

2019year10month8day The crushing and grinding operations are an important part of the processing of mineral resources, and it is also operation with high investment and high energy consumption. In the case of metal mines, equipment investment in crushing operations accounts for 65% to 70% of the total plant value, power consumption is about

узнать больше

Crusher - an overview ScienceDirect Topics

Mechanical Crushing and Grinding. Oleg D. Neikov, in Handbook of Non-Ferrous Metal Powders, 2009 Crushers. Crushers are widely used as a primary stage to produce the particulate product finer than about 50–100 mm in size. They are classified as jaw, gyratory and cone crushers based on compression, cutter mill based on shear and hammer

узнать больше

Global energy consumption due to friction and wear in the mining industry

2017year11month1day The energy consumed in U.S. for mining industry comes from 34% diesel, 32% electricity, 22% natural gas, 10% coal and 2% gasoline. Materials handling was in average the largest energy consumer (42%) followed by processing (39%) and extraction (19%). Diesel fuel is mostly used in material handling to 87% [221], [222].

узнать больше

Crushing and Screening Handbook - AusIMM

2021year6month24day TABLE OF CONTENTS Chapter Subject / section name Preface Table of Contents Metso’s Mining and Construction Technology 1 Quarry Process + Process Integration and Optimization (PIO) 2 Feeders 3 Crushing Equipment 3 C-Series Jaw Crushers 3 Superior MK-II Primary Gyratory Crushers 3 GP Series Cone Crushers 3 MP

узнать больше

Crushing Energy Efficiency - North American Mining Magazine

2021year6month10day According to one estimate, the mining industry consumes 12EJ per year of energy – or 3.5% of total final global energy consumption.1 The energy intensity of mining is also predicted to increase over time as deposits that are lower quality, deeper and more difficult to extract are mined.

узнать больше

Crushing and Grinding: Two Important Parts in the Mining Industry

The machinery can be called pulverizer and grinding mill .The machinery that combine the crushing and grinding can be called crushing and grinding machine. In the cement industry, the role of broken grinding costs in the cement works are around 20% of production costs, and electricity consumption of crushing machinery accounts for about 10% of ...

узнать больше

(PDF) SIZE REDUCTION BY CRUSHING METHODS

2017year3month4day The process "Comminution" involves size reduction and size-wise classification called as screening or separation. The objective of this report is to provide the details of size reduction methods ...

узнать больше

Effects of drying and grinding in production of fruit and vegetable ...

2016year11month1day The market for dehydrated fruits and vegetables has actually known a rapid growth rate (of 3.3%) for most countries worldwide (Zhang et al., 2006). Dried fruits and vegetables are widely used by the confectionary, bakery, sweet and distilling industries in various sauce, teas, puddings, garnishments and food for infants and children.

узнать больше

Crush vs Grind: Usage Guidelines and Popular Confusions

2023year10month16day Exception 4: Crushing Vs. Grinding In The Mining Industry. In the mining industry, the terms “crush” and “grind” have very specific meanings. “Crushing” refers to reducing large rocks into smaller rocks or gravel, while “grinding” refers to turning large rocks into small particles or powder. The two processes are often used in ...

узнать больше

Influence of Natural Aggregate Crushing Process on Crushing

2021year7month27day Crushing is one of the most energy-consuming technological processes. The purpose of grinding is to achieve the desired grain size of mineral raw materials. The process of grinding consists of many factors, for example, the size and form of crushed grains, as well as their mutual arrangement inside the crushing machine chamber, the

узнать больше

A comparative study on the effects of dry and wet grinding

2019year9month1day However, in the industry, wet grinding is the common method for particle size reduction, ... HPGR can process a wide range of coarse crushing to very fine grinding [23], [24]. ... (2011), pp. 267-275. View PDF View article View in Scopus Google Scholar [34]

узнать больше

- дробилка за дърво вибокс

- профиль компании из мельницы

- добыча дробилка Казахстане

- линейное вибросито цена обработка материалов

- хромовой руды процесс добычи

- портативный бетон дробилки аренду годовых

- вибропитатель пвг 1.23

- мобильный грохот для просеивания

- золотой руды стиральные машины производители в Киргизия

- купить дробилка для щебня стоимость Компания Зенит

- тонн в час цена мобильные дробилки

- конусная дробилка по англииски

- применения мельницы для кориандра мельница

- вторая рука план щековая дробилка

- песок кварцевый песок стиральная Китай